About Elon Musk New Car

New Summer arrivals

Choose what you like on all

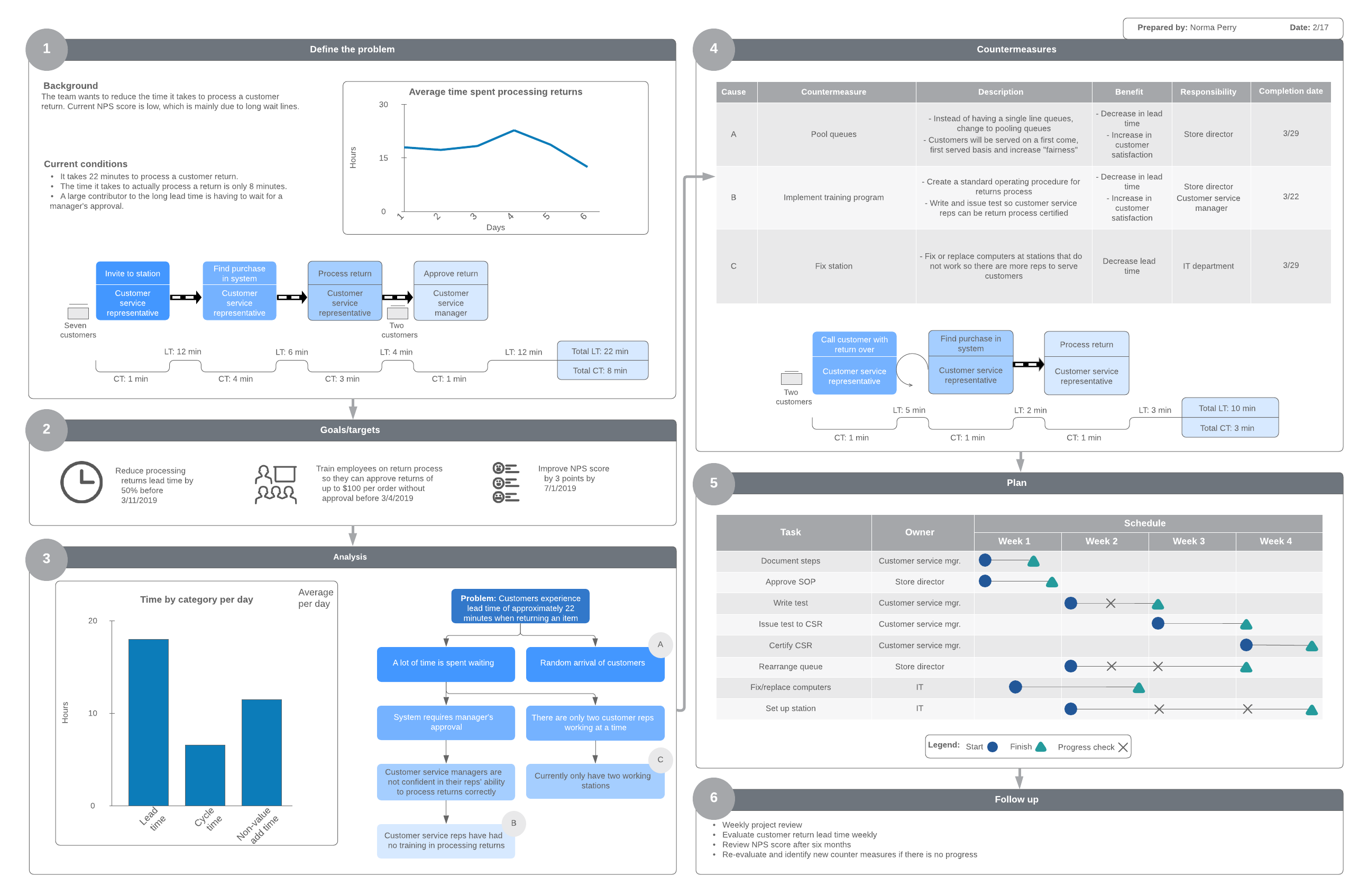

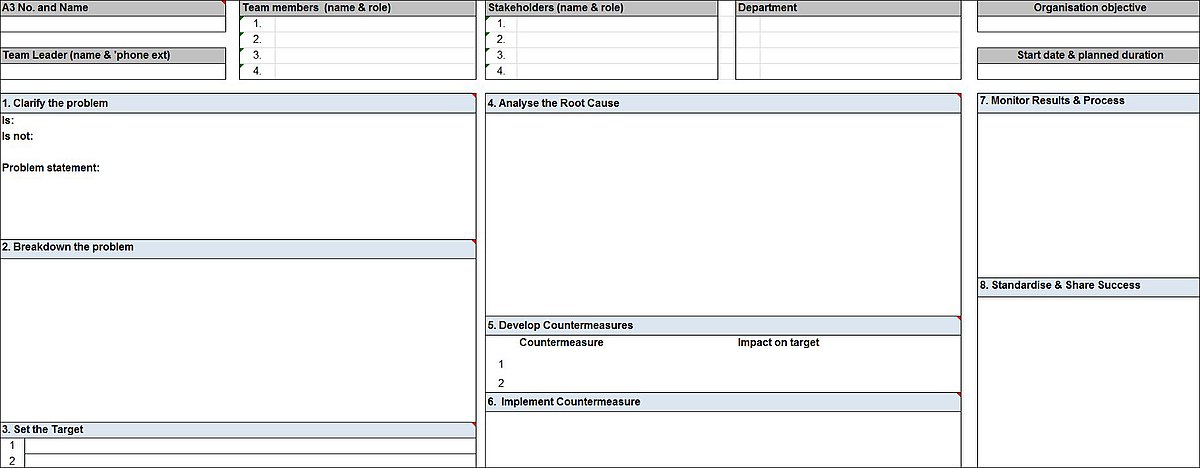

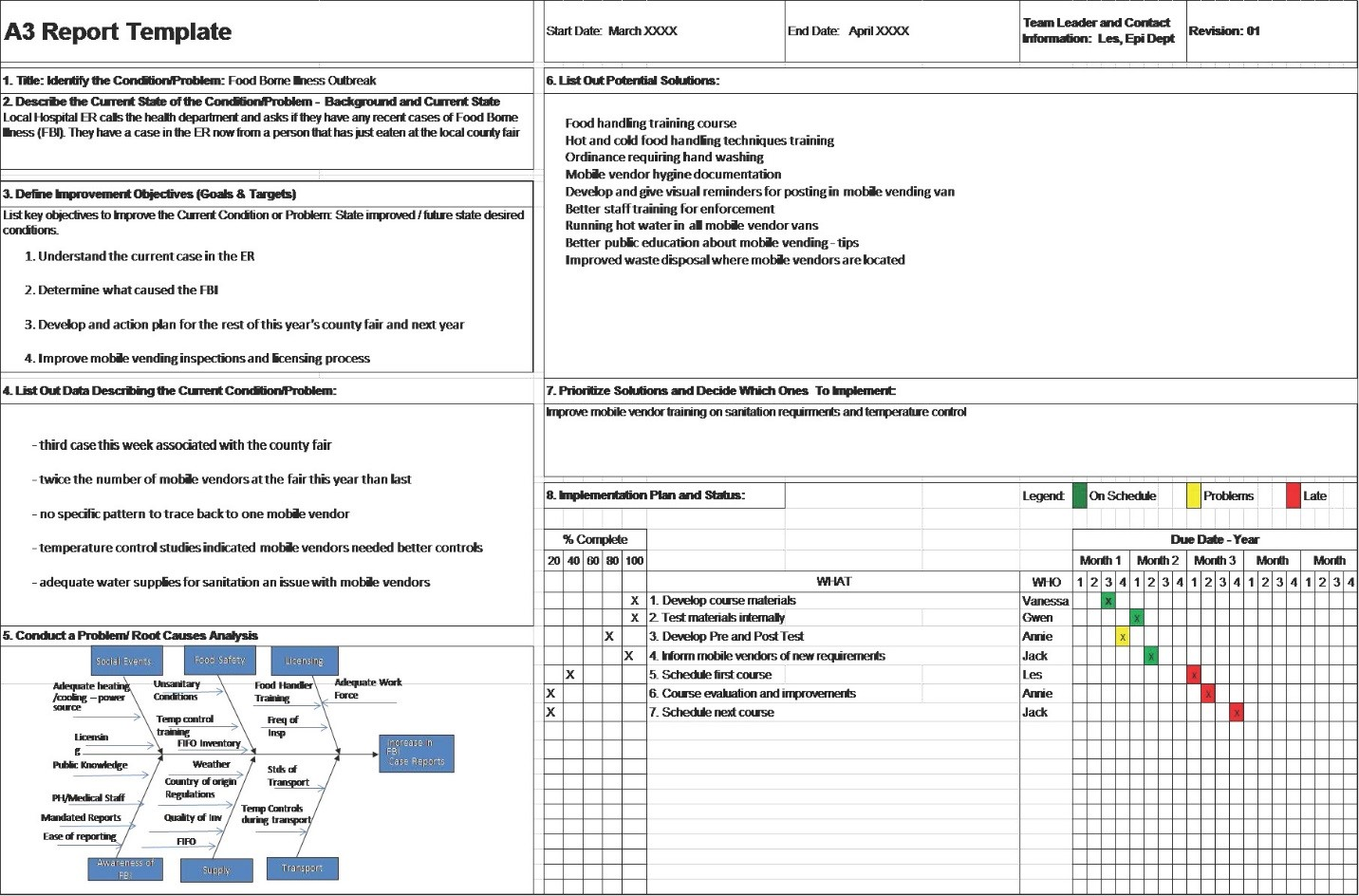

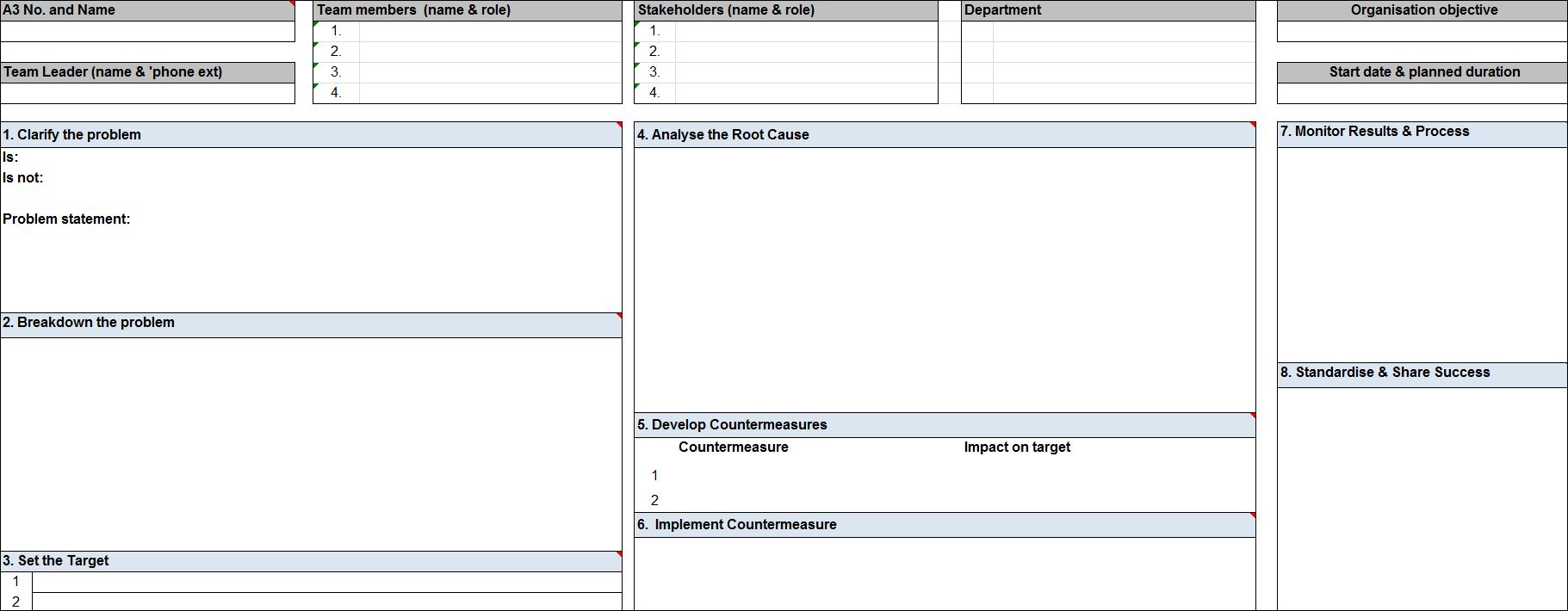

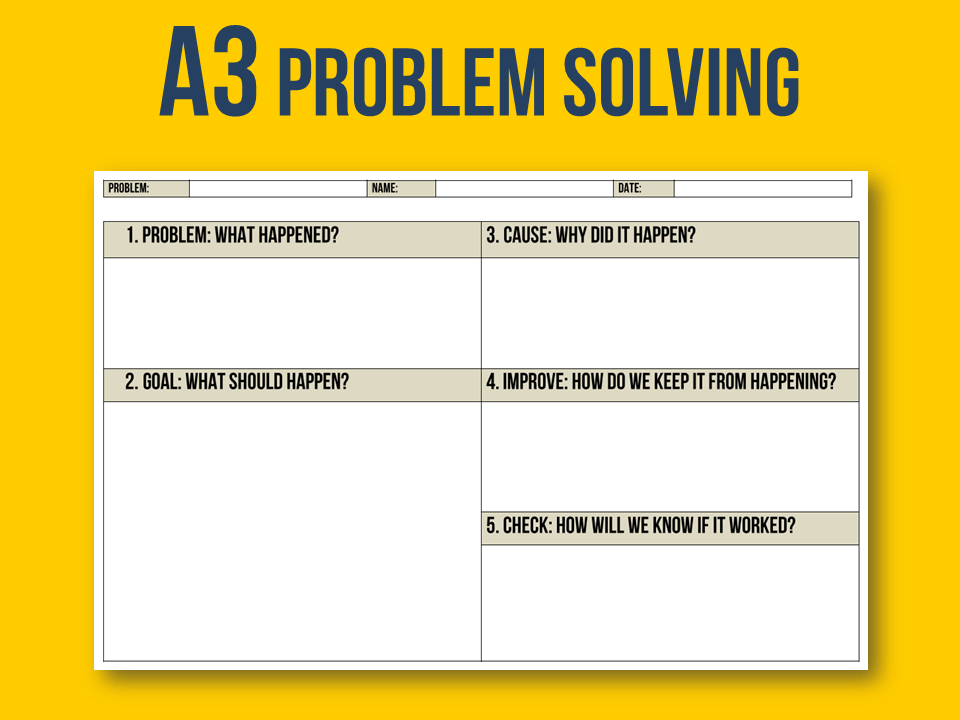

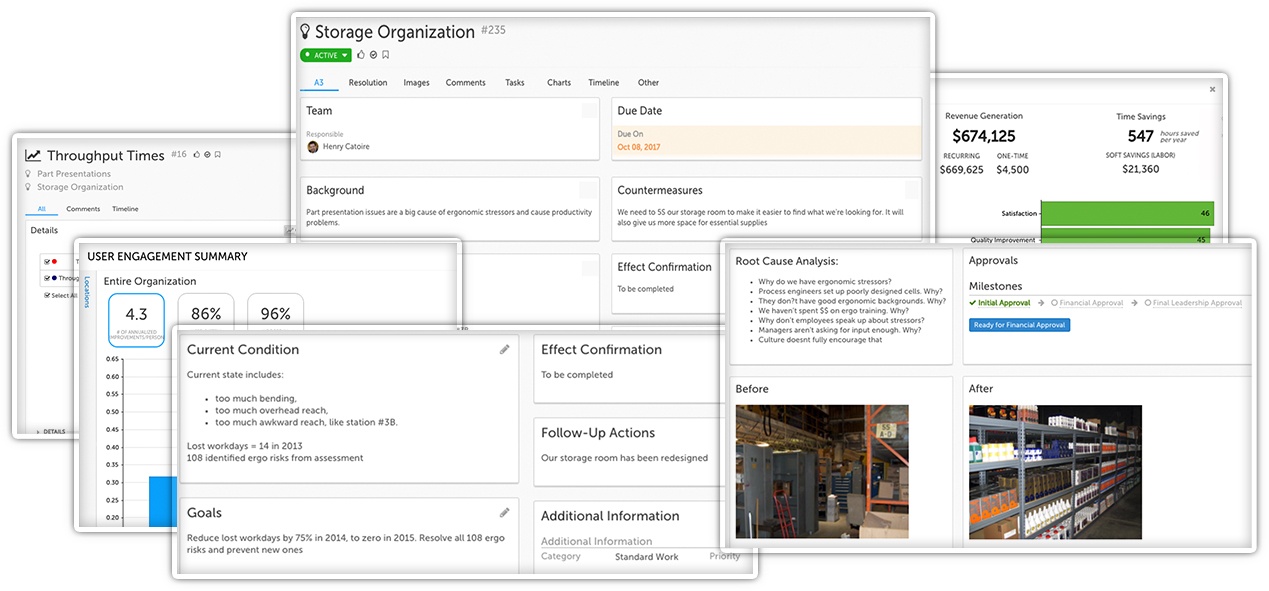

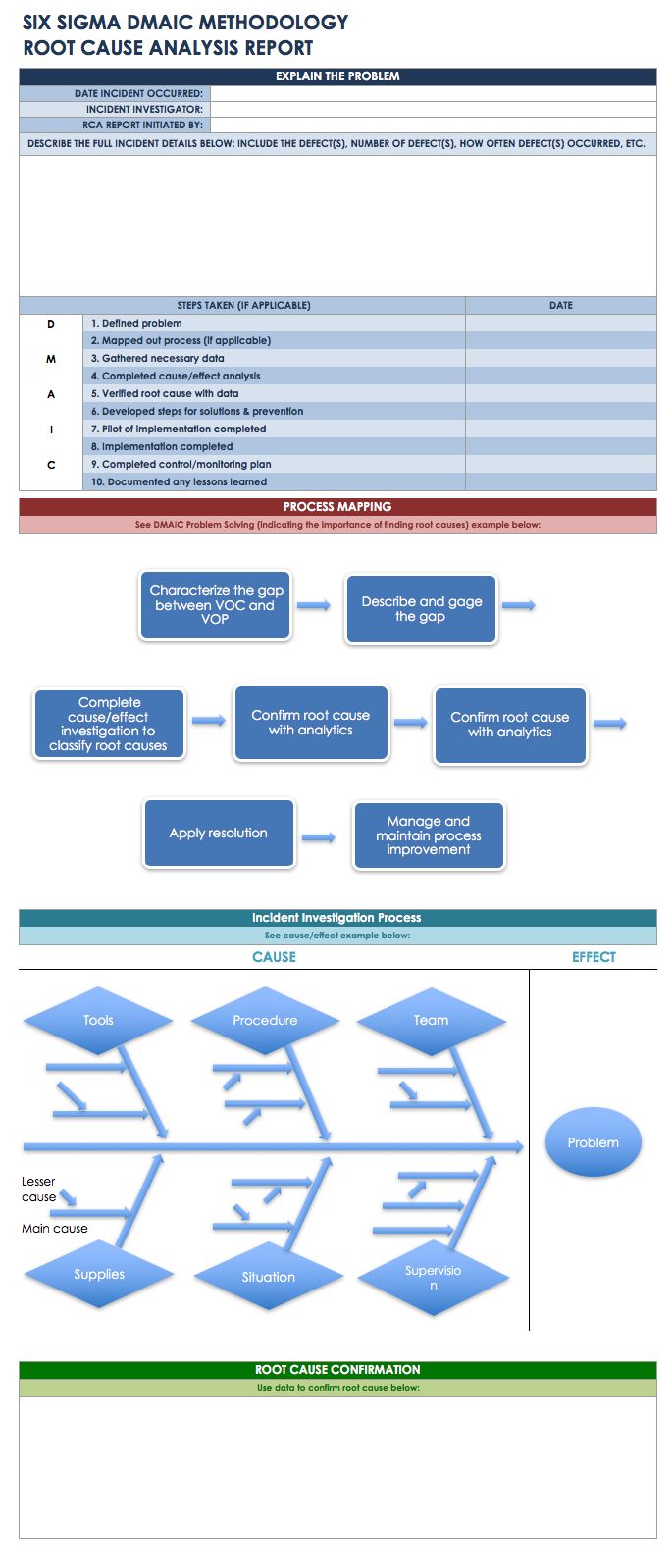

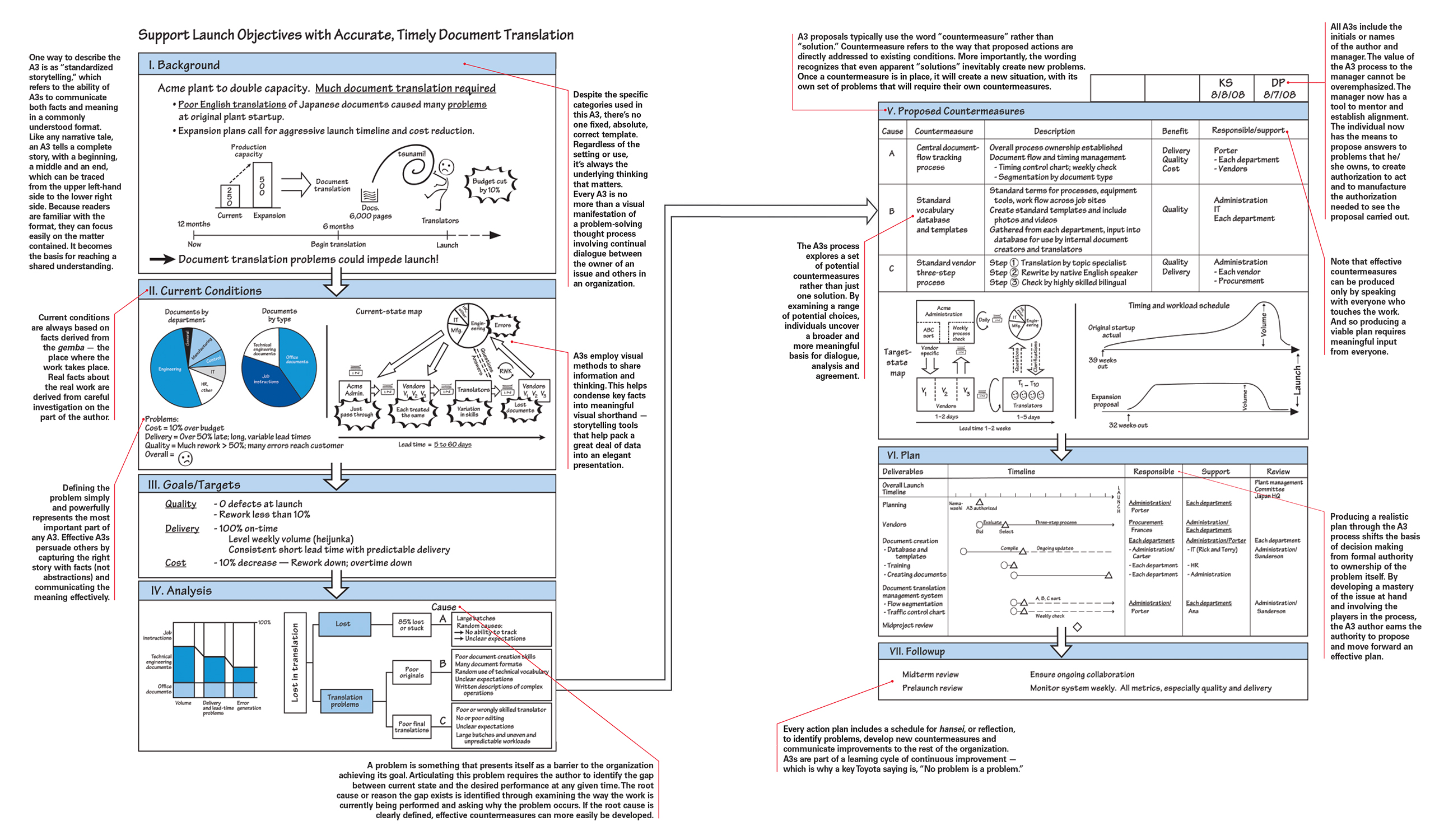

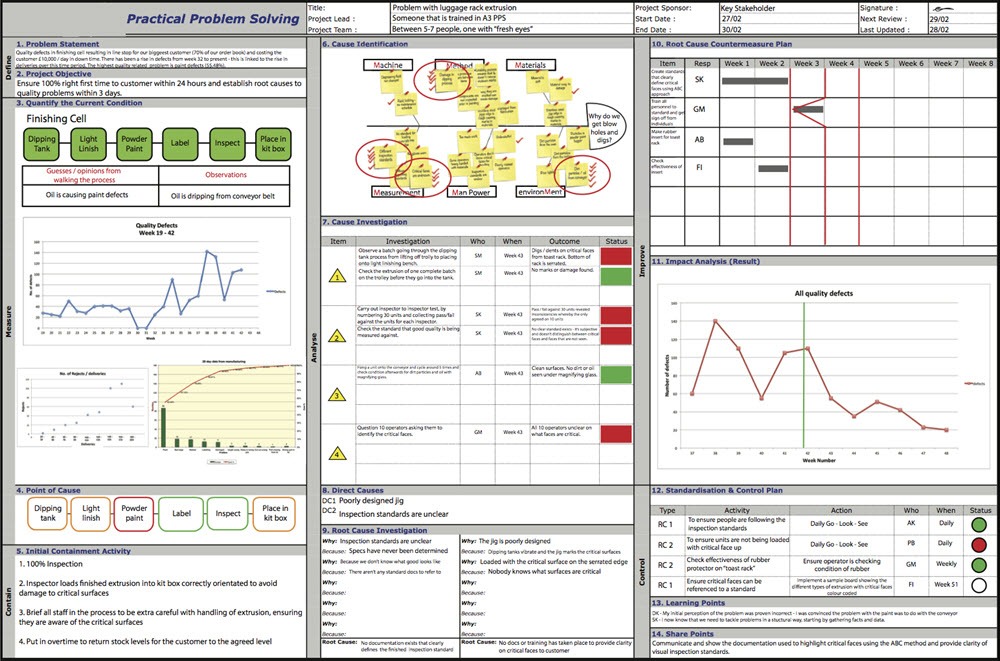

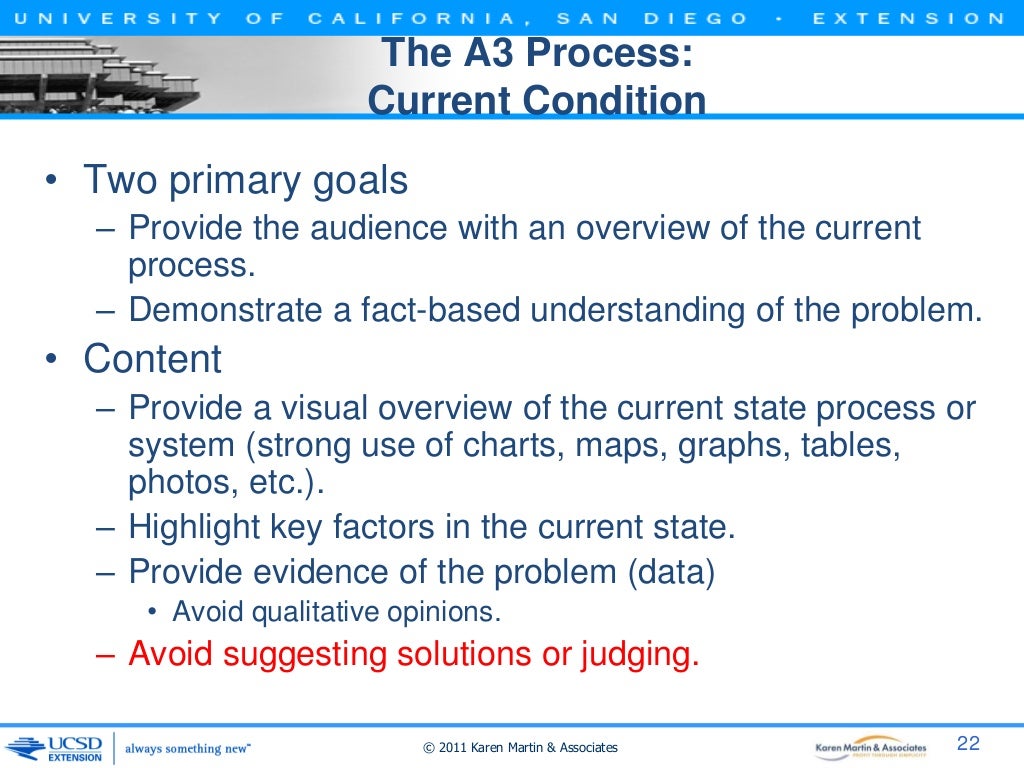

A3 Quality Method

A3 is an approach to problem solving that grew out of lean manufacturing at toyota.

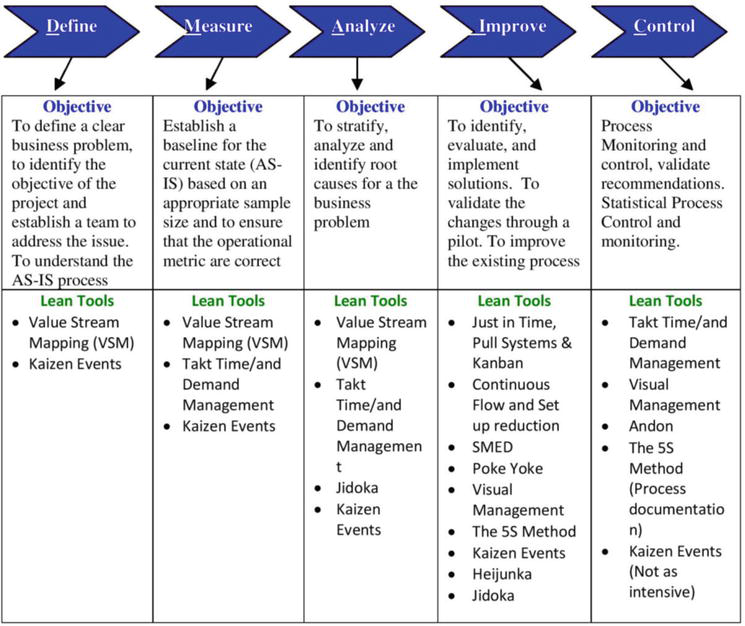

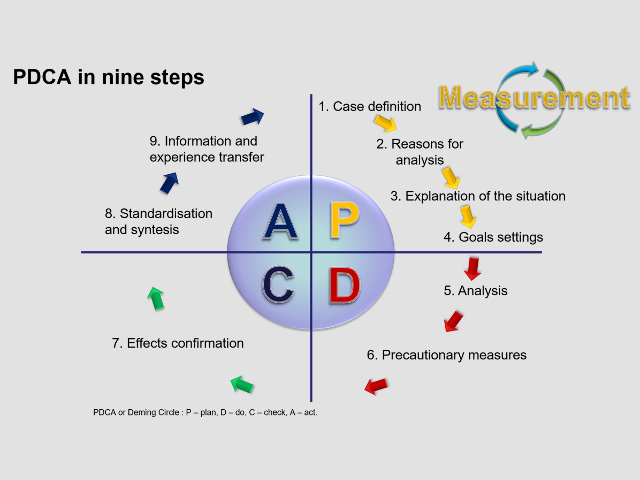

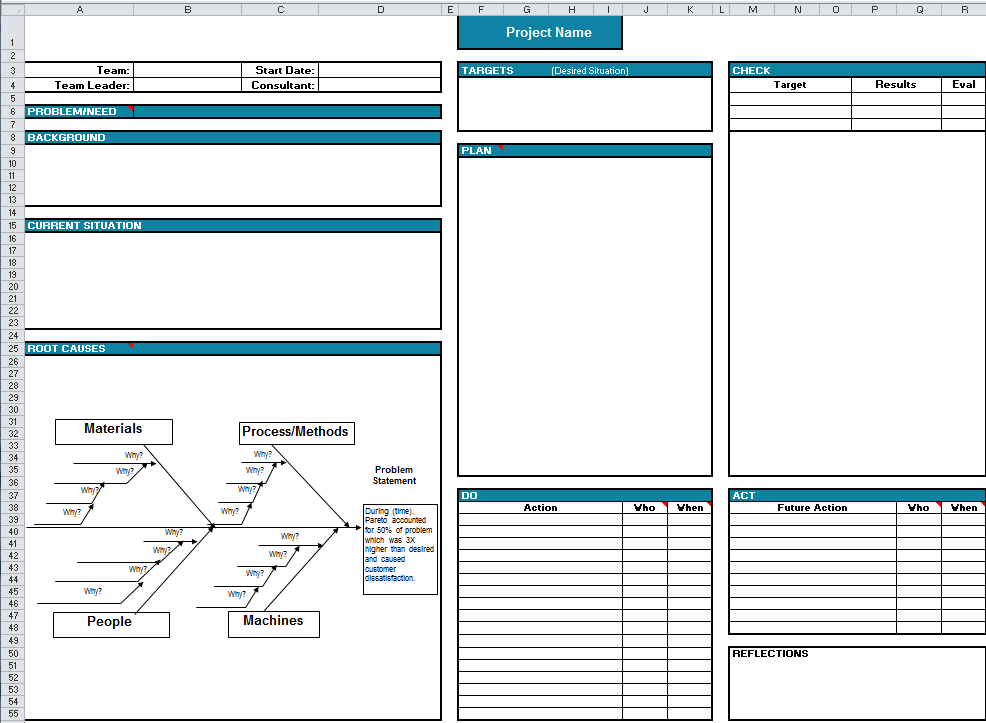

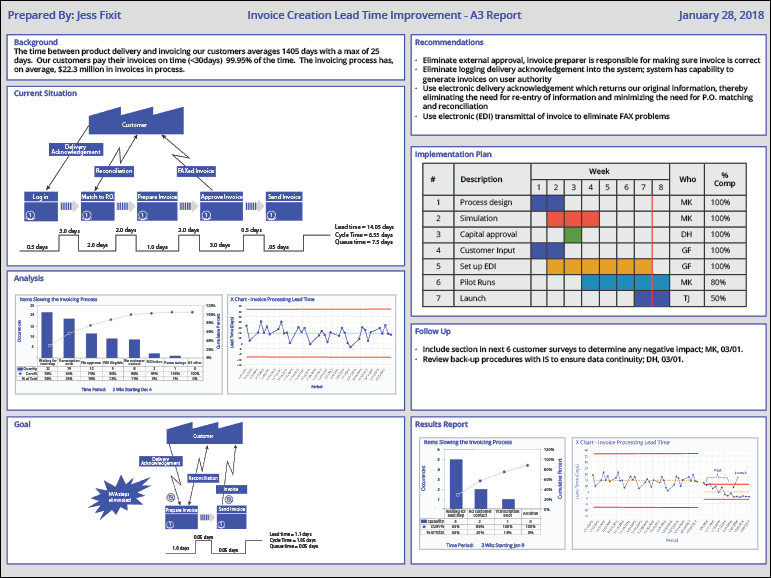

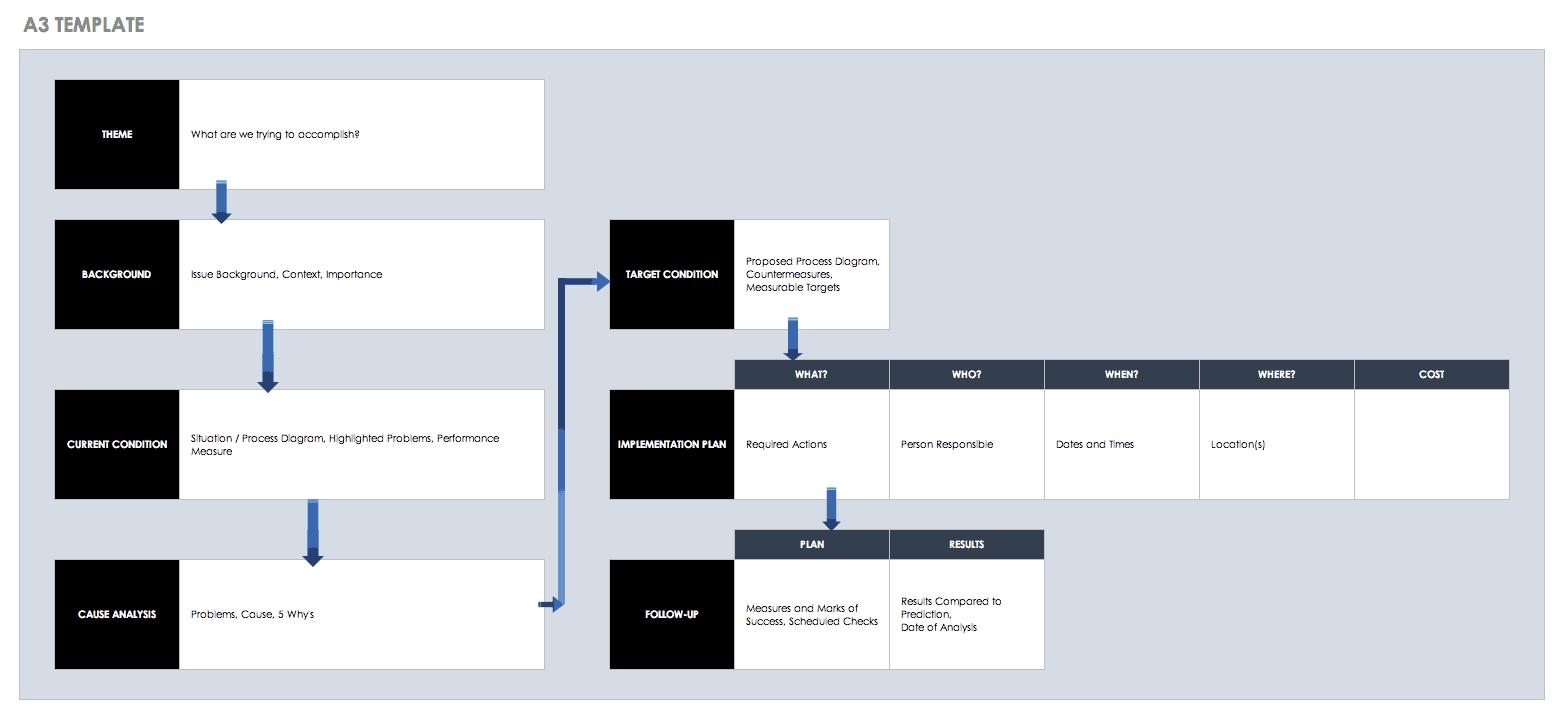

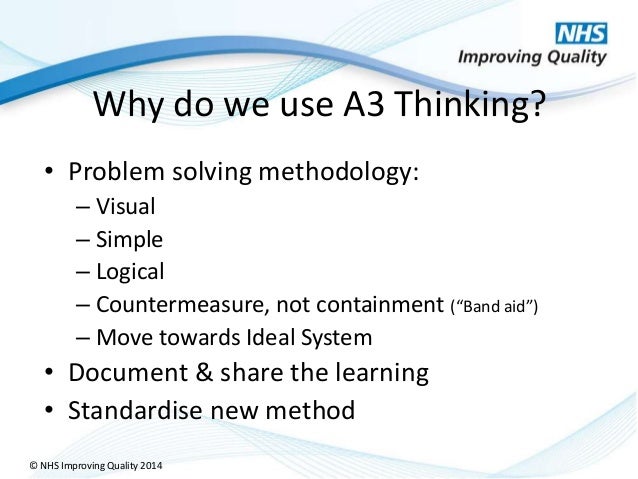

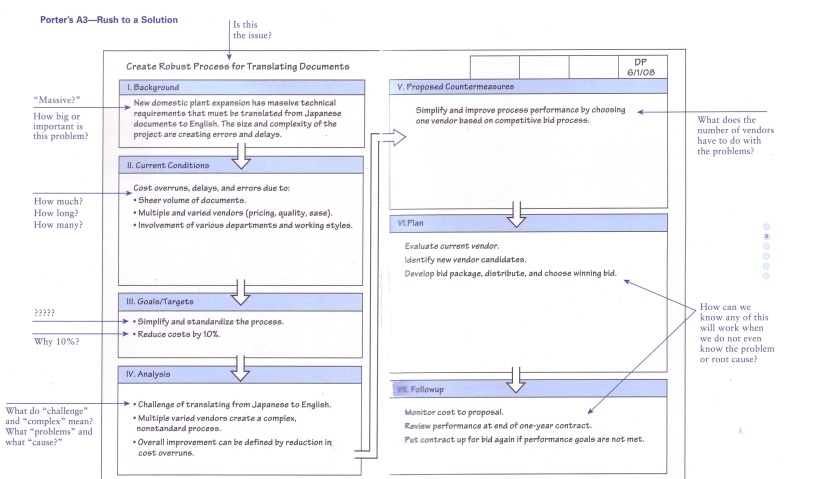

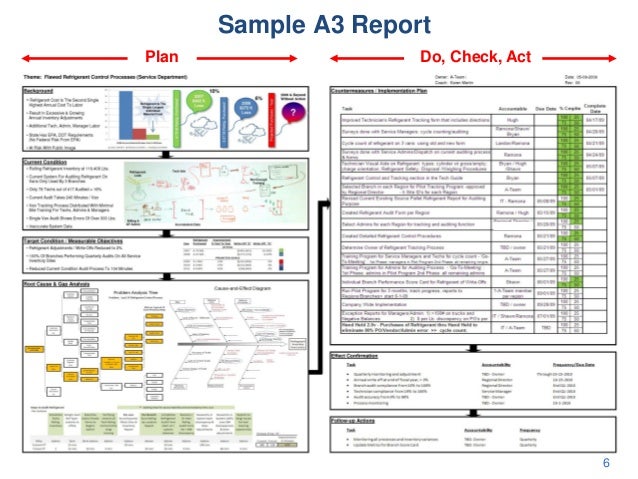

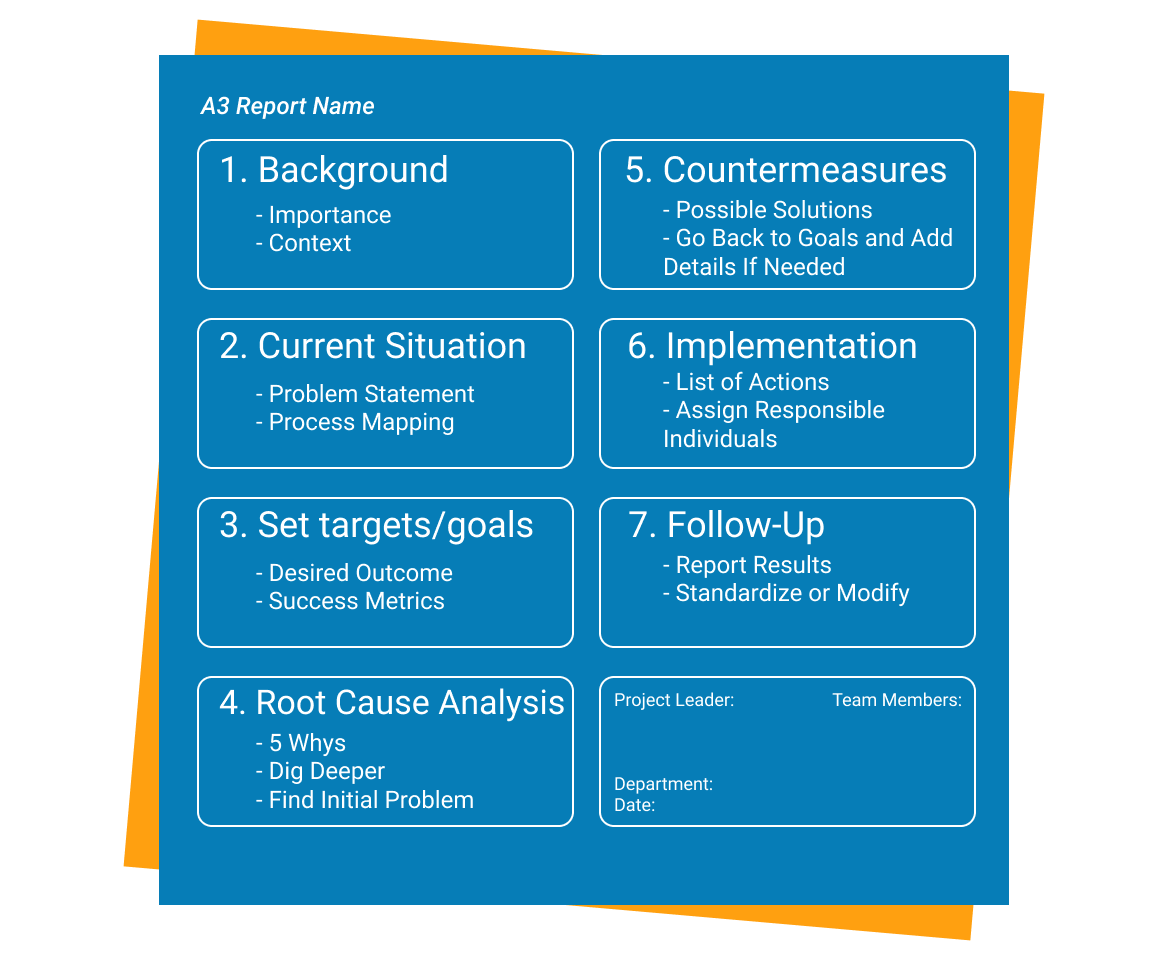

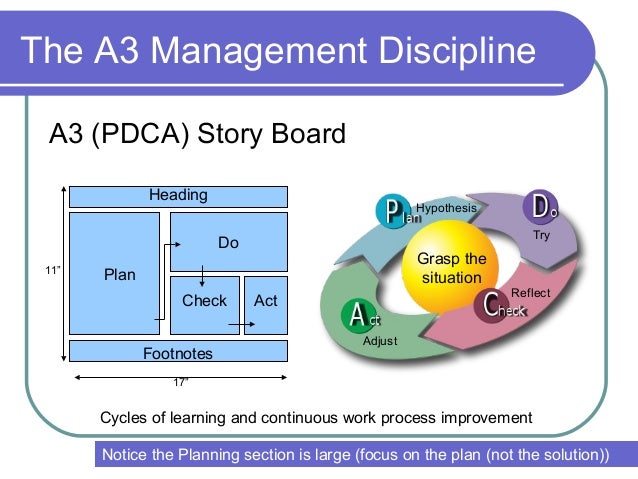

A3 quality method. This is a starting point where the. A3 problem solving steps using a very simple approach a3 problem solving is composed of the following seven steps shown below. The a3 report is based upon the plan do check act pdca method.

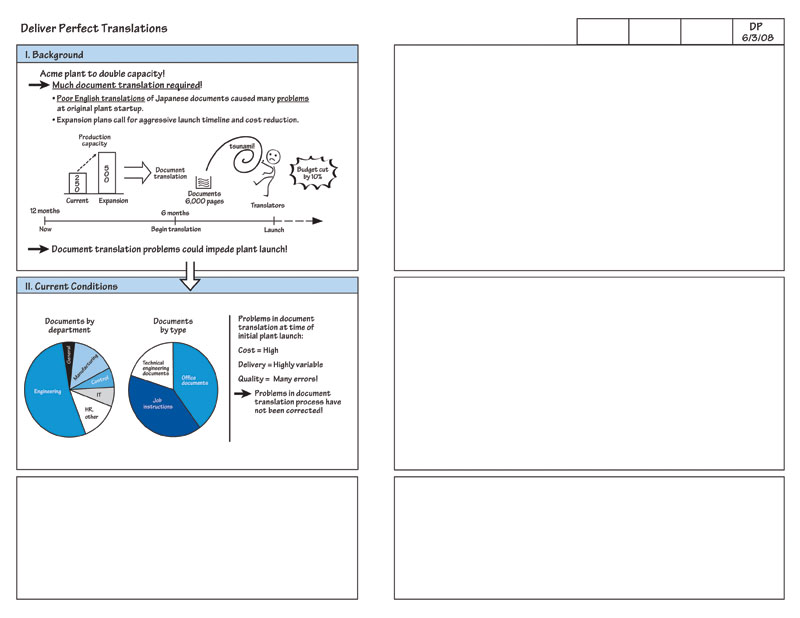

Toyota uses a3 reports for several common types of work. The name a3 is actually derived from a standard european paper size similar to 11 by 17. What is a3 problem solving.

Do you want to bring the a3 methodology into. The pdca process is sometimes referred to as the deming wheel or deming circle. Background in this step you make the business case for selecting a particular problem for resolution.

After the current. Before a problem can be addressed properly the problem owner needs to describe the current situation. The a3 report incorporates this basic premise to problem solving and continuous improvement.

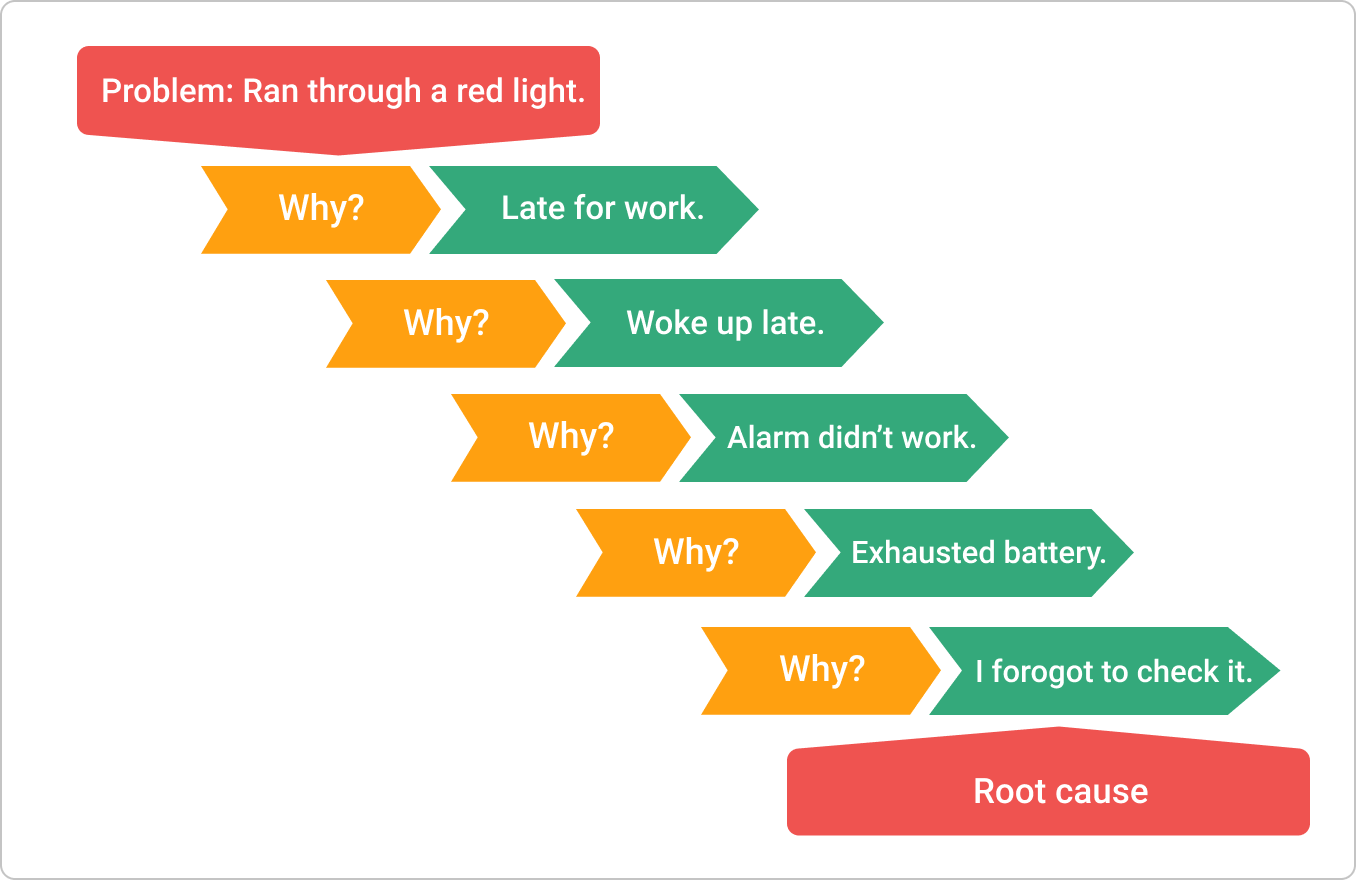

Thus repetition is reduced. A3 problem solving is a structured problem solving and continuous improvement approach first employed at toyota and typically used by lean manufacturing practitioners. A3 leads towards problem solving over the structure placed on an iso iso a3 single sheet paper.

It provides a simple and strict procedure that guides problem solving by workers. These steps are basically. By documenting this part of the a3 thinking process the people involved will have a better understanding of the working method and the problem analysis and problem resolution will have more structure.

First of all you need to clarify the problem and briefly describe it. The a3 process background. The approach typically uses a single sheet of iso a3 size paper which is the source of its name.

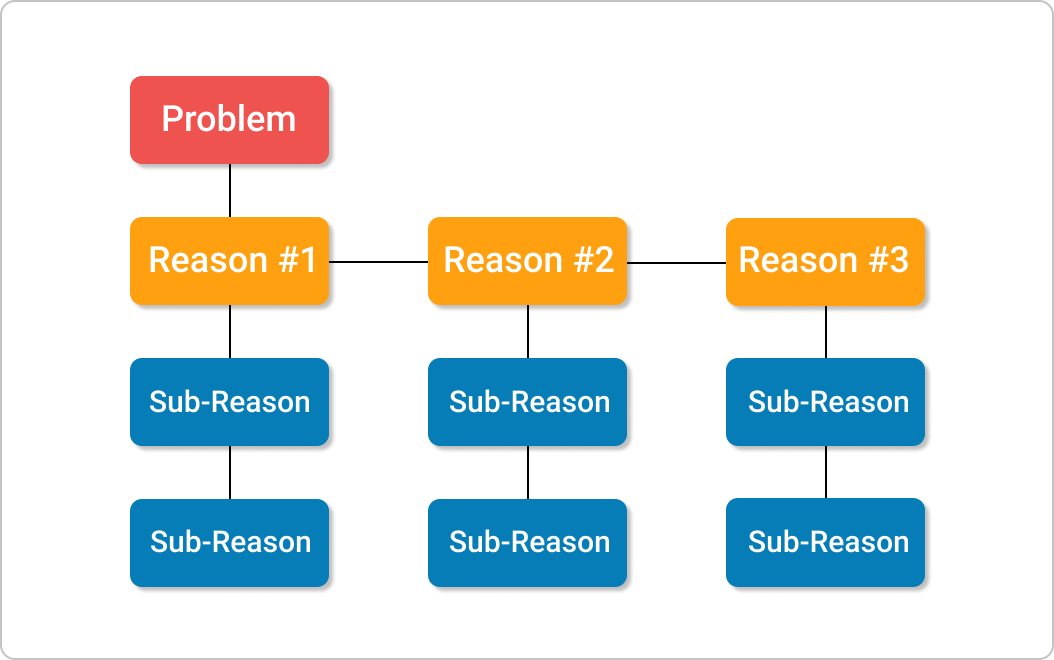

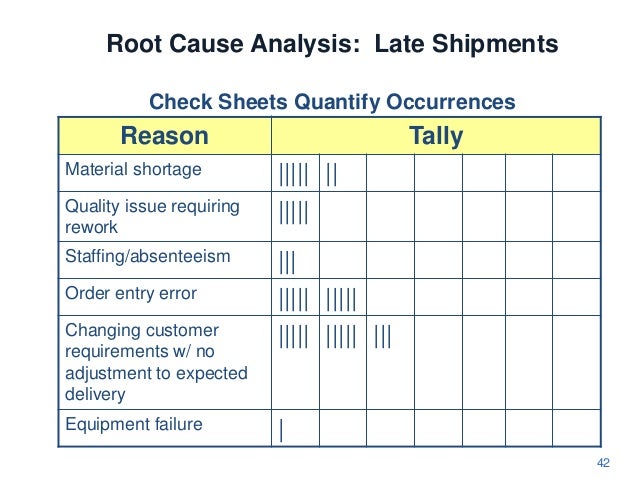

Identify the problem or need understand the current situationstate develop the goal statement develop the target state perform root cause analysis brainstormdetermine countermeasures create a countermeasures implementation plan check results confirm the effect update. The a3 process is a problem solving tool toyota developed to foster learning collaboration and personal growth in employees. Steps 0 up to 6 will be included in the a3 report.

From our blog

What's new in the ? Check our blog!